📧 info@aupower.com

📞 +918839669262,9893637789

⚡ Battery Regeneration Center Raipur

📧 info@aupower.com

📞 +918839669262,9893637789

⚡ Battery Regeneration Center Raipur

Advanced pulse-based regeneration systems designed specifically for Lead-Acid & SMF batteries to restore performance and extend usable life.

AU Power uses globally proven pulse-regeneration and diagnostic systems designed specifically for Lead-Acid & SMF (VRLA/AGM/GEL) batteries. This technology helps reduce sulphation, improve charge acceptance, and restore usable performance—in some cases allowing batteries to remain in service for up to 2 additional years when their internal condition supports recovery.

Optimized regeneration processes ensure maximum efficiency with consistent and reliable performance.

Robust design and industrial-grade components ensure long operational life with minimal maintenance.

Industrial-grade battery regenerators engineered for reliability, efficiency, and multi-battery processing.

RG-4X

RG-4X

High quality regenerator capable of processing 4 batteries simultaneously.

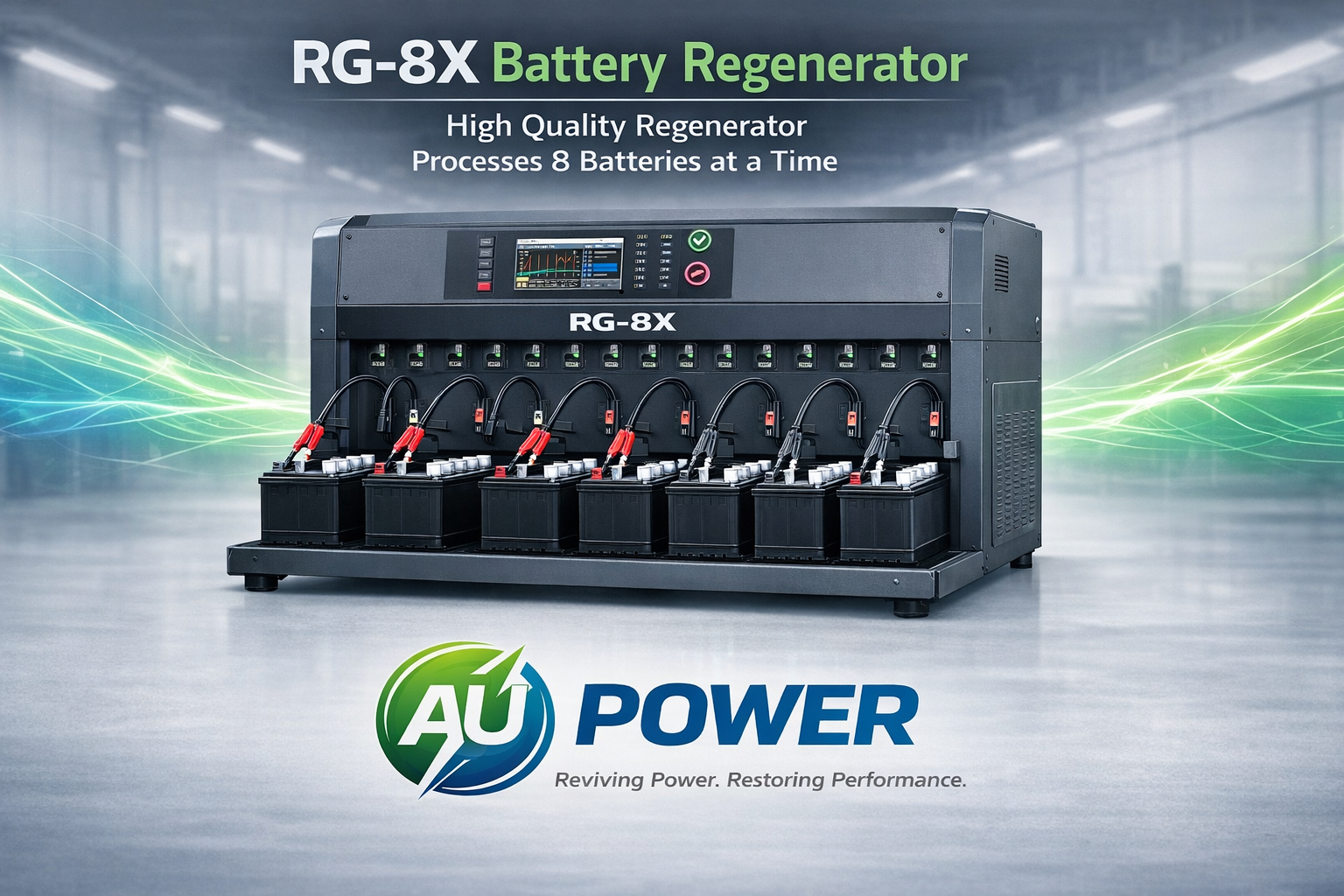

RG-8X

RG-8X

Designed to regenerate 8 batteries at a time with pulse-based technology.

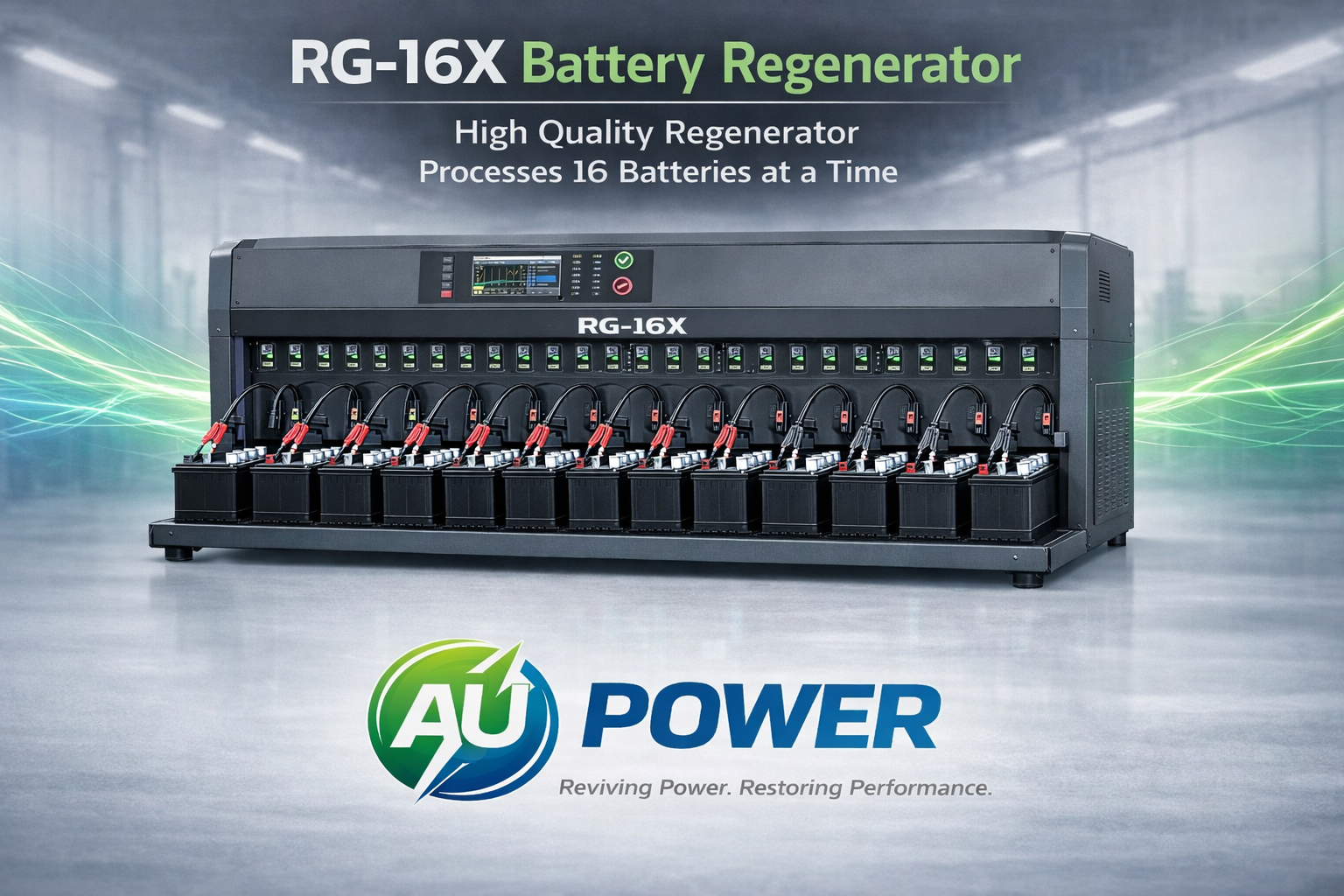

RG-16X

RG-16X

Heavy-duty regenerator suitable for large battery banks and factories.

A structured and controlled regeneration process designed to restore battery performance safely and effectively.

Targeted electrical pulses help dissolve sulphate buildup on battery plates and recover charge retention.

Controlled conditioning cycles stabilize internal chemistry to improve battery efficiency and performance.

Optimized regeneration cycles restore usable capacity wherever recovery is technically feasible.

Batteries are tested before and after regeneration to validate performance improvement and stability.

Technology exists to improve results — not to replace batteries or sell machines.

Our service infrastructure uses advanced regeneration and testing systems to ensure safe, accurate, and effective battery recovery.

Our regeneration solutions support critical infrastructure and power-dependent industries where reliability is essential.

Reduce replacement costs, improve performance, and extend battery life with AU Power’s advanced regeneration solutions.

Trusted by government and institutional clients across industries.

Clear answers to common questions before battery regeneration service.

Yes. Pickup and on-site diagnostics are available in these cities.

Since they are outside Raipur limits, travel/logistics cost applies and is confirmed after:

Travel cost is communicated upfront — no hidden charges. If approved, we schedule the visit. Otherwise, batteries may be brought to Raipur.

Inside Raipur: Yes, subject to feasibility.

Outside Raipur: Only if travel cost is approved or minimum batch size is met.

No. Phone information is not diagnostics. Physical testing is required to confirm feasibility.

Only pickup/logistics charges apply. No regeneration charges are taken if we don’t proceed.

Case-by-case basis. If tampering is detected, we may reject the battery for safety or performance reasons.

Cost is decided after diagnostics based on battery age, condition, capacity, and quantity. No assumptions or phone promises.

Based on distance, battery quantity, and technician time. Charges are communicated clearly before dispatch.

We guarantee the process, not assumptions. Backup duration depends on battery condition confirmed after testing.

We re-evaluate. If the issue is external (charger, inverter, wiring mismatch), it is not a service fault.

We disconnect batteries if accessible. Rack removal and electrical work is customer’s responsibility.

Team returns and travel cost still applies. Customer must ensure batteries are accessible.

No. Regeneration is a smart step before replacement, not a reset to brand-new condition.

No. Mixed-age battery banks reduce performance and reliability.

Before pickup or service approval, the customer must confirm the following:

If the above details are not provided, the service will not be scheduled.